From cobots and exosuits to digital twins and lights-out warehousing, we dive into the major technological changes shaping the warehouses of the future.

The warehouse of the future will be very different from the warehouse of today.

Today, these facilities are filled with people moving quickly around, using handheld scanning devices and other decades-old automation equipment to pick, sort, package, and ship items.

In the future, there will only be the quiet humming of robots without a person in sight. They operate in total darkness and the space is barely heated or cooled — just enough to protect the products and robotics — saving on energy and cost. The robots move in harmony, grabbing items from shelves and delivering them to conveyor belts. An automated packaging system makes a custom box perfectly sized for the goods.

Drones fly through the air, scanning products embedded with RFID tags and transmitting real-time data on item locations and quantities. Every robot’s movement is tracked and fed into a machine learning algorithm that strives to make everything quicker and more efficient as it connects to the wider supply chain ecosystem.

the state of Supply Chain & Logistics Tech q1 2022

Total supply chain funding remains elevated in Q1’22. Get the report to learn more.

This highly automated system is called “lights-out warehousing”, where robots, sensors, and advanced algorithms take the place of human workers.

But before we reach lights-out, various technologies to augment the human worker will continue to gain ground. From cobots to exosuits, the industry is adopting new tech at a fast rate — thanks to the commercialization of IoT devices, decreasing costs of robotics, and advancements in AI, among other factors.

In this report, we cover the key technologies shaping the future of the warehouse, including:

- Cobots that work alongside humans to make them more productive

- Drones for scanning and moving items, slashing the time it takes to manage inventory

- AR and VR for improving worker training and reducing errors

- Exosuits that can make warehouse workers safer and more efficient

- Digital twins and advanced analytics systems for enabling complete operational visibility

- Advanced robotics that can help deliver the vision of a fully automated, lights-out warehouse

- The “industrial internet of everything” where every device in the warehouse is linked to each other and to the broader supply chain

But first — what’s at stake?

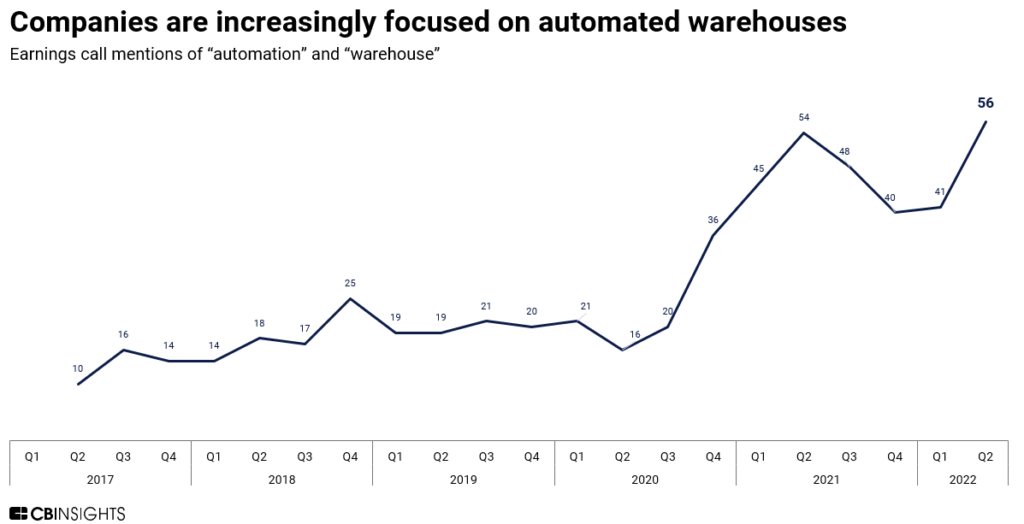

Why it matters: Automation and efficiency are critical amid the growth of global e-commerce and rising consumer expectations around faster shipping times. Bain & Company estimates that automation could reduce warehousing operating costs by 13% by 2030.

While standard automation techniques — such as conveyors, sortation systems, and handheld scanners — have been used for decades, warehouses are starting to adopt more intelligent and connected technologies that can improve efficiency and bring down costs. This will drive continued growth in the global warehouse market — with the sector projected to reach $326B by 2024, according to CB Insights’ Industry Analyst Consensus.

The first technologies to make headway will likely make workers more productive without replacing them. However, complete automation and total supply chain interconnectedness are the end goals. Robotics will eventually allow for full worker replacement in many warehousing applications.

Why now: It’s more important than ever to make warehouses more efficient, as global supply chains recover from the pandemic, people spend more money on goods, and consumers demand ever-faster delivery.

Want to see more research? Join a demo of the CB Insights platform.

If you’re already a customer, log in here.