From humanoid robots to AI copilots, we break down how companies are using generative AI to drive next-gen industrial automation.

Generative AI is poised to permeate all aspects of the manufacturing landscape, bringing greater efficiency to operations and sharpening decision-making along the way.

While most genAI initiatives are still in early stages of development, incumbents and startups are betting heavily on its potential.

ABB, for instance, has identified over 100 internal applications for the tech, from robotics to predictive maintenance. Retrocausal, which develops a computer vision-enabled AI copilot for the assembly line, estimates that genAI can reduce manual assembly time by a third.

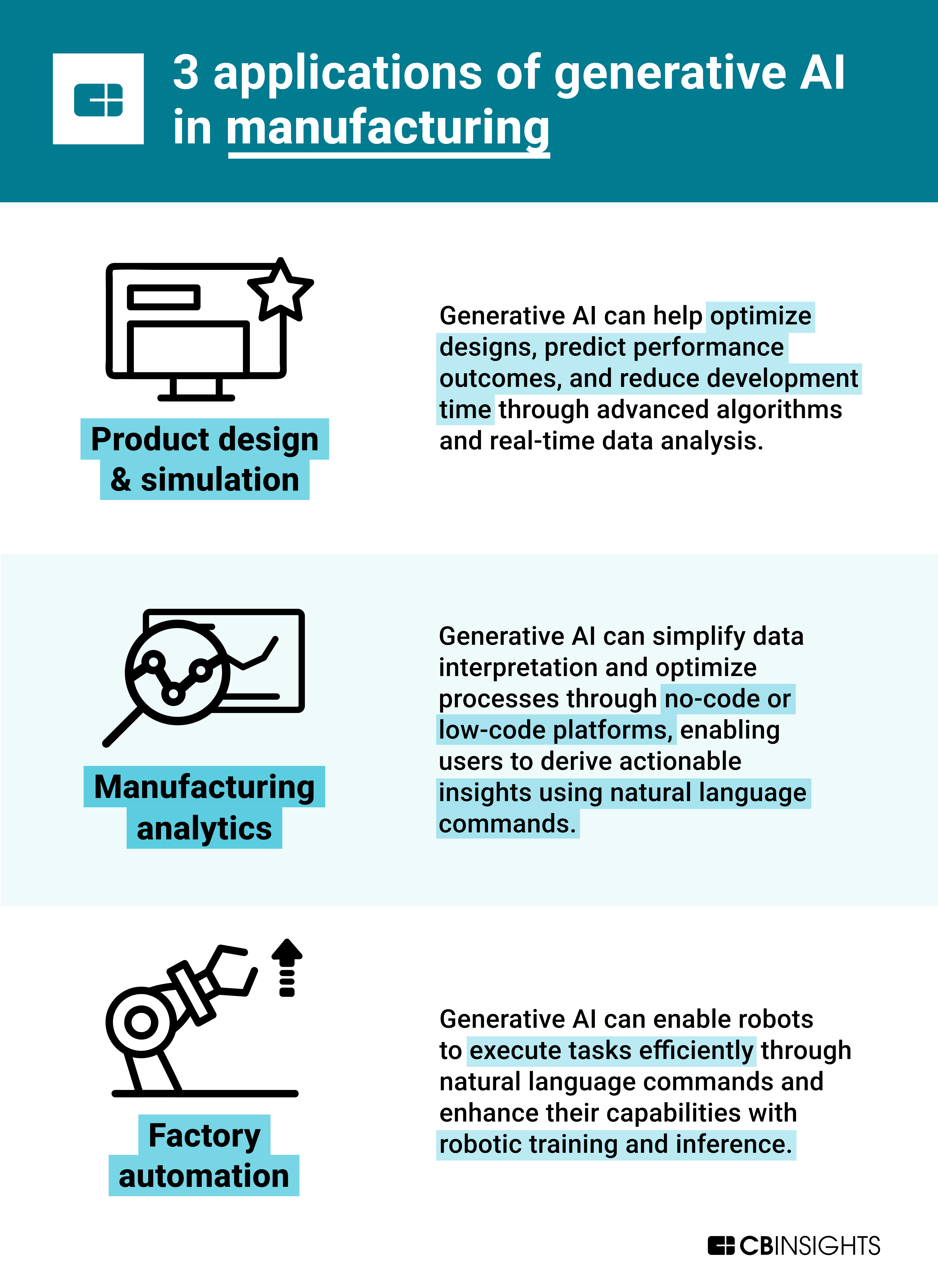

Below, we explore how advanced manufacturing companies are using generative AI to improve product design & simulation, drive manufacturing insights, and unleash new capabilities in factory automation.

Product design & simulation

Product design & simulation

While generative design dates back decades, leaders are now integrating generative AI into traditional computer-aided design (CAD) and engineering simulation software. These capabilities let engineers input design goals and constraints to rapidly generate and test design variations.

Want to see more research? Join a demo of the CB Insights platform.

If you’re already a customer, log in here.